|

| LEADER OF ELECTROLYSIS TECHNOLOGY |

Introduction of Super Aqua new-generation sterilization techniques

The Statement

The functions, features, or applications of the hypochlorous acid or its products on this website are described in usages or actual cases is for reference only. If the application may involve medical application or efficacy, effectiveness etc., should based on the doctor's judgement. We request our client to apply for relevant certification to your Health Authority in accordance with your relevant laws and regulations in each country. We would like hereby declare the above matters.

1. Technical background of Super Aqua

(1) 1,000 patents over 40 years:

The know-how of Super Aqua for electrolyzed functional water were originally developed from Okazaki Manufacture Technology (OMT) which has been researching electrolyzed functional water for four decades and owns 1,000 industry-leading patents and techniques.

The 100% hypochlorous-acid liquid is the core technique first developed by Chiarman T. Okazaki, from Okazaki Manufacture Technology (OMT) and a revolutionary product changing the history of sterilization and contributing to the Earth as well as human and environmental health.

(2) Industrious applications:

The technique of hypochlorous-acid liquid has attracted attentions from different industries including more than thousands of foods & beverages manufactures and medical institutes for its applications, for example, many brewery,food,beverage 、national hospital、and dental clinics. The technique has potentials for applications to various industries in the future.

1、History of functional sterilizing water

First generation: sodium hypochlorite (bleaching water)

High-concentration sterilizing water, a.k.a. sterilizing king

Original sodium hypochlorite liquid: concentration>12%; pH>12

Advantages:

- Strong antibiosis and efficacy (condition: high concentration)

- Fewer residues; safety at low concentrations

- Economy; wide applications

Disadvantages:

- Transformation to alkalinity after increase of the concentration

- Detrimental to skin and mucous membrane

- Strong metal corrosion degrading rubber or plastic

- Dilution of original liquids before use (danger)

∇

Second-generation: functional sterilizing water

Strong-acid water; high efficacy; instability

(The functional sterilizing water is derived from electrolysis in salty water.)

- Corrosive substance

- Chlorination

- Degradation attributed to organics

Concentration of hypochlorous acid=10~50ppm (0.001~0.005%); pH<2.7

Advantages:

- Low-concentration available chlorine (hypochlorous acid) with strong sterilization effect on many bacteria

- No residue

Disadvantages:

- Available chlorine (hypochlorous acid)

- Strong metal corrosion

- Sterilization effect degraded due to existence of few organics

- Chlorination

∇

Third-generation: Super Aqua sterilizing water

Optimized sterilizing water: 100% hypochlorous-acid sterilizing water

Low concentration; high efficacy; concentration of chlorine <1ppm

Concentration of hypochlorous acid (electrolyzed)=50~80ppm (0.005~0.008%); pH=4.0~7.0

Concentration of hypochlorous acid=100~200ppm/500ppm (0.01~0.05%); pH=4.5~6.5

Free effective chlorine for sterilization effect is molecular hypochlorous acid.

Advantages:

- High-concentration hypochlorous acid (50~80ppm or 100/500ppm)

- Safety: chlorinated sterilizing water<1ppm

- Environment-friendly: sterilizing water reduced to water and trace salt

- HACCP/GMP certificates

- High safety and low metal corrosion

- Wide applications

2、Animal safety test report

| Acute toxicity test | No abnormality |

|---|---|

| Single skin irritation test | No irritation |

| Eye irritation test | No irritation |

| Multiple skin irritation test | No irritation |

| Sensibility test | Inaction |

| Cytotoxicity test | No trouble |

| Mutagenic activity test | No mutagenicity |

<Inspector: Public Interest Incorporated Foundation BioSafety Research Center,Japan (BSRC)>

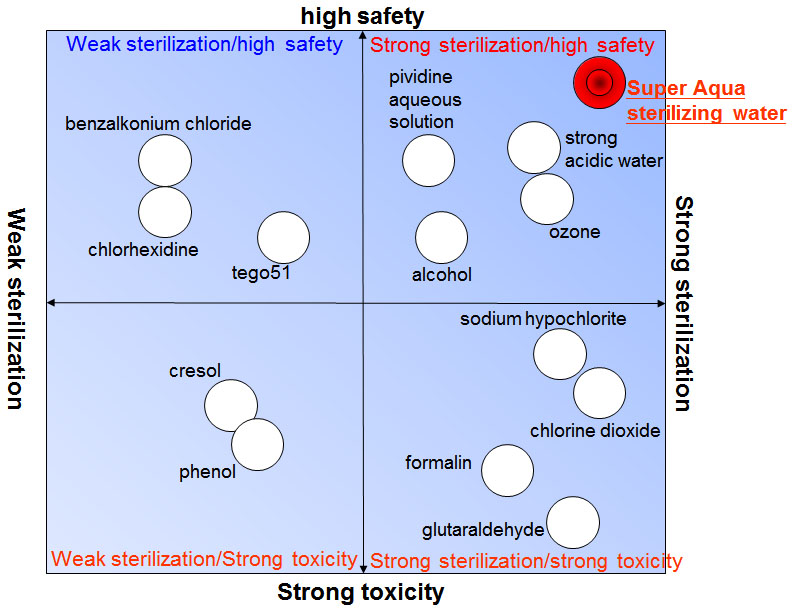

3、Concept, sterilization effect and safety of sterilizing water

Concept, sterilization effect and safety of sterilizing water

- The conventional disinfectants are characteristic of good effect but strong toxicity or good safety but poor effect usually, i.e., two properties contrary to each other.

- Strong-acid water and ozone water which features good effect and high safety compared with the conventional disinfectants can be taken as an ideal solution.

- Super Aqua sterilizing water, which is free of the problems of strong-acid water and ozone water such as gasification of active ingredients and corrosion, is the first priority of a customer for sterilization.

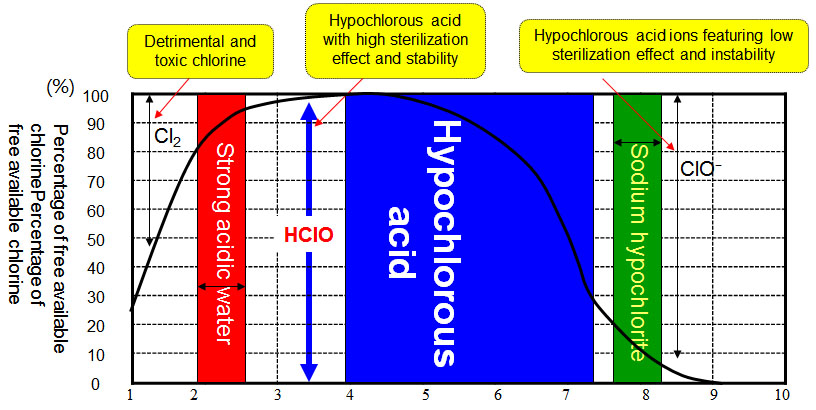

4、Sterilization effect of free effective chlorine

Chemical reaction: H2O+Cl2

- Hypochlorous acid (HClO)---→free effective chlorine

- Hypochlorous acid ion (ClO-)↗

- Chloride ion (Cl-)→ No sterilization effect (e.g., seawater)

Free effective chlorine with sterilization effect

The comparisons for hypochlorous acid with different pH values are shown as follows:

Literature: “Technique of Clean Water”, Norihito Tambo & Koichi Ogasawara, Gihodo Shuppan Co. Ltd., 1985

5、Sterilization effect of HClO (hypochlorous acid) which is 80 times as much as that of ClO- (hypochlorous acid ion) theoretically

Comparisons of sterilization effect between Super Aqua sterilizing water and sodium hypochlorite

Time to destroy 99% of E. Coli (unit: minute)

Example: Time to kill bacteria with 0.1 mg/L chlorine

| HClO | About 1.5 minutes (benchmark=1) |

|---|---|

| ClO- | About 120 minutes (80 times) |

| NH2Cl | About 520 minutes (350 times) |

Source: Environmental Protection Administration (EPA), U.S.A.

6、Sterilization effect tests of sterilizing liquids

| Names of Bacteria | Total Plate Count (1 ml) | |||

|---|---|---|---|---|

| Initial count | After 1 minute | After 3 minutes | After 5 minutes | |

| Escherichia Coli | 4.3×106 | <10 | <10 | <10 |

| 4.3×106 | <10 | <10 | <10 | |

| Staphylococcus aureus | 4.5×106 | <10 | <10 | <10 |

| 4.5×106 | <10 | <10 | <10 | |

| MRSA | 3.4×106 | <10 | <10 | <10 |

| 3.4×106 | <10 | <10 | <10 | |

| Salmonella | 3.4×105 | <10 | <10 | <10 |

| 3.4×105 | <10 | <10 | <10 | |

| Pseudomonas aeruginosa | 1.6×105 | <10 | <10 | <10 |

| 1.6×105 | <10 | <10 | <10 | |

| Streptococcus | 1.9×106 | <10 | <10 | <10 |

| 1.9×106 | <10 | <10 | <10 | |

| Bacillus | 4.6×106 | 3.7×105 | <10 | <10 |

| 4.6×106 | 4.4×106 | 4.5×106 | 4.5×106 | |

| Candida | 2.3×106 | <10 | <10 | <10 |

| 2.3×106 | 4.4×106 | 4.5×106 | 4.5×106 | |

| Aureobasidium pullulans | 2.0×105 | <10 | <10 | <10 |

| 2.0×105 | 2.0×105 | 50 | <10 | |

Pink ground: Super Aqua sterilizing water residual chlorine: 57 ppm

White ground: sodium hypochlorite effective concentration: 200 ppm

* Initial count: Microbial count for no sterilizing water added

* <10: detection limit (no bacteria detected)

Overview of Super Aqua new-generation sterilization techniques

SuperAqua vs. Strong Acidic Water

Super aqua is nearly 100% hypochlorous acid liquid (HOCl water).

Not likely the strong avidic water which the HCLO is unstable and easily gasifying and also easy cause the corrosive on equipment. Super Aqua is with nearly 100% hypochlorous acid liquid

which is the best ideal HCLO water for sterilization or disinfection in any area.Please refer to the following link.

Related Journals about Sterilizing Water

Japan Soft Drink Journal, March 1998 (Extra edition)

Japan Beverage Technology 1998

(Only Chinese version is available)

Cleaning and sterilization techniques of acidic sterilizing water used in aquatic products

By Dr.C.C.Huang, The Food Industry Research and Development Institute (Taiwan)

(Only Chinese version is available)

Electrolysis Technique Applied to Cultivation of Non-toxic Shrimps

Because of prosperous shrimp culture in Taiwan, the annual yield and the output value of white shrimps only are approximately 8,000 tons and NTD 1.5 billion, respectively. However, the yield and quality of shrimps based on the traditional aquaculture technique are influenced by hazardous bacteria inevitably.

For diners eating shrimps safely, there has been an innovative technique known as high-pressure water flow sterilization for circulation of seawater in culture ponds with no antibiotics added.

English

English  繁體中文

繁體中文  简体中文

简体中文